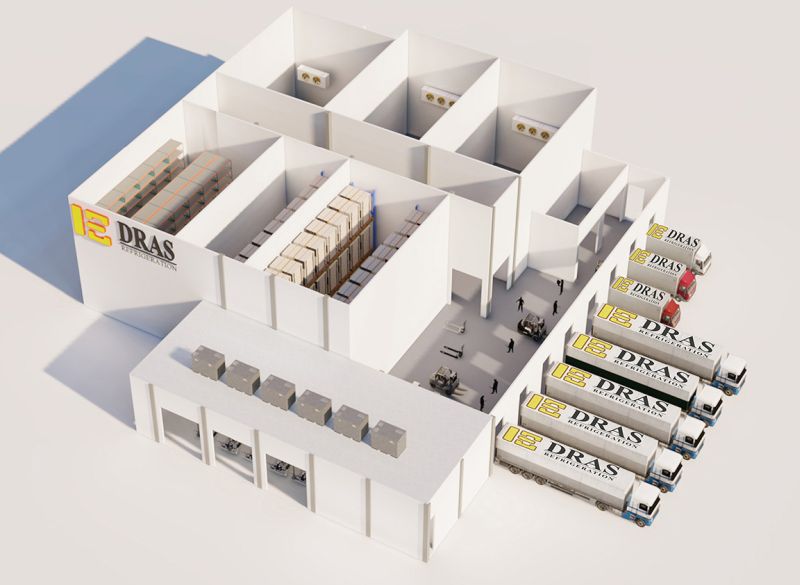

Cold Room Malaysia

A cold room company essentially refers to the person or company that manufactures a specific cold storage or mass-produced cold storage solution designed to meet the necessary requirements for a cold storage and provide value-for-money transactions to customers who place orders.

A cold room company have several decades of experience as cold room manufacturers, it has grown into a market leader in the design, installation and maintenance of refrigerators. A company not only produce world-class products, but also take pride in unparalleled maintenance record. They follow up on every item their deal with closely and often ask for maintenance of cold rooms they may not have created yet.

They adopt highly advanced technical methods in their equipment and systems. Their equipment, systems, products and services are tightly coupled with a high level of expertise and cost savings. They do not outsource work and they assure customers with high standards of quality and service control.

All cold room refrigeration systems have four main components:

The compressor

The air conditioning compressor is the heart of the cooling system. It is the most misdiagnosed component of the system. It helps to remove hot steam refrigerant from the evaporator system of the air conditioning unit. In layman’s terms, a compressor condenses vapor into a reduced volume at high temperatures. Some compressors work with pulleys and belt systems, and some use electric motors.

The compressor includes a reed valve that helps it regulate the circulation of the refrigerant during the pumping process. If it is not fastened securely, gas may penetrate the low-pressure side during the compression stroke.

Most compressor units consist of a safety valve that helps control the pressure of the unit. If the system discharge pressure exceeds normal values, the valve will automatically open and remain open until the pressure drops. The noise you receive from the air conditioner can also point to the compressor stand.

The Condenser

The condensing unit is the most important part of the entire cold room system. The condensing unit is usually the high-pressure side component of the refrigeration system. It is a component of compressor, condenser, fan motor, controller and mounting plate. It has the function of a heat exchanger for cooling and condensing incoming refrigerant vapor into a liquid, and a fan for blowing external air through the heat exchanger section to cool the internal refrigerant. Condensing units come in a variety of designs and a wide range of sizes, from small household appliances to very large industrial units used in food and manufacturing processes.

Expansion Valve

The expansion valve releases pressure from the liquid refrigerant, thereby expanding the liquid in the evaporator to vapor or changing from vapor to vapor.

The high-pressure liquid refrigerant entering the expansion valve is hot. This can be verified by feeling the liquid line at the connection to the expansion valve. The liquid refrigerant leaving the expansion valve is too cold. The orifice in the valve does not dissipate heat, it only reduces pressure. Therefore, when the refrigerant moves out of the orifice, the heat molecules contained in the liquid refrigerant can disperse. At greatly reduced pressure, the liquid refrigerant is in the coldest state when it leaves the expansion valve and enters the evaporator.

In most systems, the pressure at the inlet and outlet of the expansion valve will be very close to the gauge pressure at the compressor inlet and outlet. The similarity in pressure is caused by the proximity of the components to each other. Small changes in pressure readings are caused by drag, which causes the pressure in the tubes and coils of the evaporator and condenser to drop.

Evaporator coil

The evaporator coil of an air conditioner, also called the evaporator core, is the part of the system that absorbs heat from the refrigerant. In other words, this is the source of cold air. The evaporator coil is located inside or near the air handler where the blower is located. Evaporator coils are made of copper, steel or aluminum because these metals tend to conduct heat. Most residential AC evaporators consist of tubes bent into a U-shape and fixed to a panel.

Panels are usually placed in the form of “A”. These panels are lined with metal flakes called “radiating fins” that bring the passing cooling air closer to the coils to maximize the role of the refrigerant. As the air conditioner runs, the compressor draws cold, low-pressure liquid refrigerant through a tube in the evaporator coil. The refrigerant passes through an expansion valve before entering the evaporator coil. The valve releases the pressure of the liquid refrigerant, which cools the refrigerant quickly. The liquid refrigerant leaving the expansion valve is very cold, which allows the refrigerant to absorb heat from the air.

Why Would Industries Use Cold Room?

- Food Processing

- Food Retail/Restaurants

- Warehouse Storage

- Research Laboratories

- I.T Data Centers

- Medical Storage

- Electronics